PAS - Our Approach

We were one of the UK’s first PAS2030 Trustmark-certified installers and have delivered large-scale projects under the Social Housing Decarbonisation Fund (SHDF) Demonstrator / Wave 1, Local Authority Delivery (LAD) Phases 1/2/3, HUG1, plus ERDF and client-funded schemes.

The PAS 2035 standard provides a framework for equipping homes with energy efficiency retrofit measures that are appropriate and effective.

Working in tandem with the Trustmark scheme, it provides consumers and registered social housing providers with confidence that retrofit works will be designed and delivered to recognised specifications and by companies that meet certain minimum standards.

All our processes and operations are aligned to the principles embodied by PAS 2035, earning us a reputation for zero-defect delivery.

Key to delivering quality and value are:

- Early and effective stakeholder collaboration

- Early planning and rapid mobilisation

- Effective, structured and continuous resident engagement

- Adherence to industry best practice

- Rigorous quality control

The following sections explain our expertise, experience and capabilities with respect to PAS-compliant projects.

- Stakeholder Collaboration

- Planning / Mobilisation

- Resident Engagement

- Best Practice and Quality Control

- Our History with PAS

Stakeholder Collaboration

It’s important that all project stakeholders know the expected outcomes and have a clear, team-wide idea of how those outcomes will be achieved at the earliest possible stage. This is key to ensuring that funding is maximised, budgets are used effectively, and that the greatest numbers of households benefit from the works.

Too often, since the introduction of the PAS standards, a lack of clarity on the part of inexperienced stakeholder teams has led to an under-estimation of costs and timescales. This is because the groups involved haven’t been familiar with the demands of the process, nor how to deliver multiple measures in a timely and efficient way. As a result, costs can escalate and the number of treated properties has to be reduced.

We help clients to avoid such problems.

From the earliest possible stage, we gather our stakeholders and adopt a shared approach to project planning, design, delivery, reporting and problem-solving. We work as a genuine team; a challenge faced by one partner is quickly shared by all.

We also agree, define and maintain clear channels of communications. We agree these at the outset with all stakeholders, and create secure, cloud-based data-sharing platforms so all parties have live access to project data and other information necessary for effective project management and cost-control.

Defining roles and accountability is also important, and strict quality controls are essential for ensuring excellent service. Maintaining those controls demands that we work to a defined plan but, importantly, that cannot be “our” plan alone as principal contractor. It must be aligned with client and stakeholder requirements and that, in turn, demands immediate multi-party collaboration.

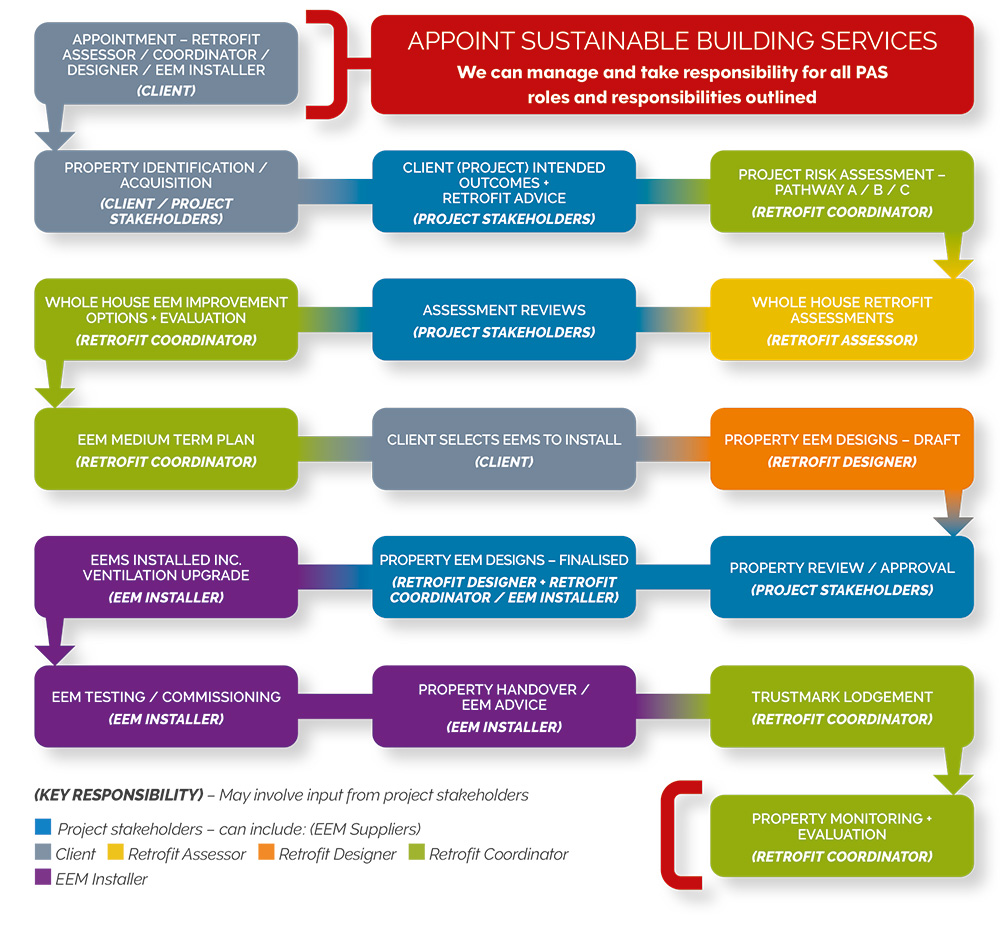

Working closely with the Client / Retrofit Assessor / Retrofit Designer / Retrofit Coordinator, we take responsibility for communication at all stages: pre-installation to completion and aftercare.

Planning / Mobilisation

A shared focus on planning, and real clarity on roles and communications all help us to mobilise quickly.

We minimise disruption and project delays through early engagement with planners, and by appointing project stakeholders as early as possible. Through collaborative working, we manage a flexible delivery programme, identifying ‘challenging’ properties at the outset, holding early discussions with utility companies, and reviewing DNO applications etc. to shorten lead-times and minimise potential delays.

This is all linked to the delivery of an early and extensive on-going resident engagement plan to help projects mobilise.

The early design input of key suppliers (e.g. for external wall insulation, doors/windows, and other low-carbon measures) is essential for securing planning consents and maximising funding opportunities for our clients. Our process therefore begins by gathering key stakeholders and the client, pre-commencement, to:

- Address planning/design issues

- Agree KPIs, project/PAS outputs and related processes

- Agree quality metrics and reporting mechanisms

At the assessment/pre-installation stage, we organise stakeholder ‘design & technical’ meetings. They are held at project inception, and then weekly, most of them usually held on-site. These meetings help us to ensure that issues are resolved, and designs approved in industry-leading timeframes, typically within weeks of project inception.

Resident Engagement

Decarbonisation and associated works, together with the individual surveys/assessments required under PAS, can feel intrusive from a resident perspective. Many clients and contractors have tended to underestimate the extent to which such works can disrupt resident routines and lead to risks such as access-refusals and extended project timeframes.

As a specialist in this field, we have long recognised that the initial engagement process is critical to a project’s success; to speed of mobilisation, timely delivery, property access and customer satisfaction.

We seek to address householders’ concerns from the very earliest stage. We do this in a structured way, according to a project-specific communication plan, our ‘Customer Journey’, and bespoke household engagement plans.

Our qualified resident-engagement teams develop household-specific engagement plans that are dynamic, adaptable and aligned to PAS2035. Moreover, we always take a proactive, personal approach to engagement, rather than relying standard letters, emails and literature. Most importantly, we induct residents within their own homes.

We spend time understanding their specific needs, identifying vulnerabilities, explaining the planned works, and detailing how each stage will affect them. Crucially, we also ensure that residents understand the benefits of their energy efficiency measures and how to make the most of them.

This all helps to preserve a genuine sense of involvement, and enables us to work flexibly, accommodating any special circumstances. It also ensures that residents can derive maximal value from the measures.

Best Practice and Quality Control

We have developed a PAS-specific supplier partnership network to support projects. Access to invaluable technical expertise at the design and planning stages invariably allows us to mobilise projects more quickly. This minimises the risks of project delays or of certain measures being removed from the programme as planned improvements.

Our supply chain partners make other important contributions to quality and best practice. Our quality-control procedures require staged checks by multiple stakeholders against defined project/PAS standards. For example, before client-handover, any newly-installed energy efficiency measure (EEM) is reviewed by our site management, EEM supplier and/or installer, and Retrofit Coordinator. This multi-party oversight has been key to maintaining our 100% handover success-rate.

Our primary role is as a PAS 2035 service provider and principal contractor. Equally, as an accredited PAS EEM installer we have invested heavily in PAS-related training within our workforce, management teams and supply chain.

This also includes in-house expertise in Retrofit Assessor and Coordinator roles, providing us with a clear understanding of the work, processes, priorities and requirements of the independent Assessors and Coordinators that we use. This drives best value for the client and residents alike, and effectively provides us with an additional tier of quality control.

Our History with PAS

Long before the introduction of the PAS 2030 and PAS 2035 standards, we had been working to similar principles and campaigning for precisely the sorts of changes that they subsequently introduced. In particular:

- For public funding mechanisms to support and encourage the installation of energy efficiency measures on a whole-house, multi-measure basis;

- For schemes to be funded, designed and delivered at scale, in order to yield valuable efficiencies and cost-savings;

- For works to be prioritised according to the benefits that they deliver to households;

- For works to be tailored according to individual property requirements;

- For some mechanism, accreditation or ‘badge’ to give householders confidence that their chosen contractor is suitably qualified and committed to meeting certain minimum standards.

Back in 2016, having already adopted quality-focused procedures that drove us in this direction, we managed a scheme that was highlighted as an example of industry best practice in the influential “Each Home Counts” report by Dr Peter Bonfield. The report gave particular emphasis to the importance of early stakeholder collaboration, effective resident engagement and channels of communication that delivered greater certainty on risks, timescales and cost.

Over the following years, we have refined and improved our systems and procedures, and our schemes continue to feature in best-practice reports and fact-finding visits by bodies such as BEIS, Trustmark and the Retrofit Accelerator.

Find out more

We offer support and advice on all aspects of decarbonisation projects: preparing funding bids, design and planning, supply chain management, project coordination and more. We also help clients to integrate plans for decarbonisation works and routine maintenance, thereby yielding cost-saving and creating less disruption for residents.