A solid wall insulation scheme delivered by Sustainable Building Services (UK) Ltd has been cited as an example of industry best practice in a major government report called ‘Each Home Counts’.

A solid wall insulation scheme delivered by Sustainable Building Services (UK) Ltd has been cited as an example of industry best practice in a major government report called ‘Each Home Counts’.

The report, produced by Dr Peter Bonfield, is an independent review of the domestic energy efficiency and renewables industry in Britain. Commissioned by the Department for Business, Energy and Industrial Strategy, and the Department for Communities and Local Government, it examines consumer advice, protection, standards and enforcement. In addition to evaluating the present state of the industry, it also sets out a clear action plan for improvement over the coming years.

The result of over 18 months of investigations and analysis, the report places great emphasis on quality and points to widely varying standards between different schemes and contractors.

‘Exemplary performance’

Clearly there have been many success stories and the report identifies an SBS scheme for Nottingham City Homes as an example of how schemes can and should be delivered.

It notes: “In conducting this Review, many examples of exemplary performance in installing energy efficiency measures have been highlighted, two of which are presented in the industry chapters of this Report.”

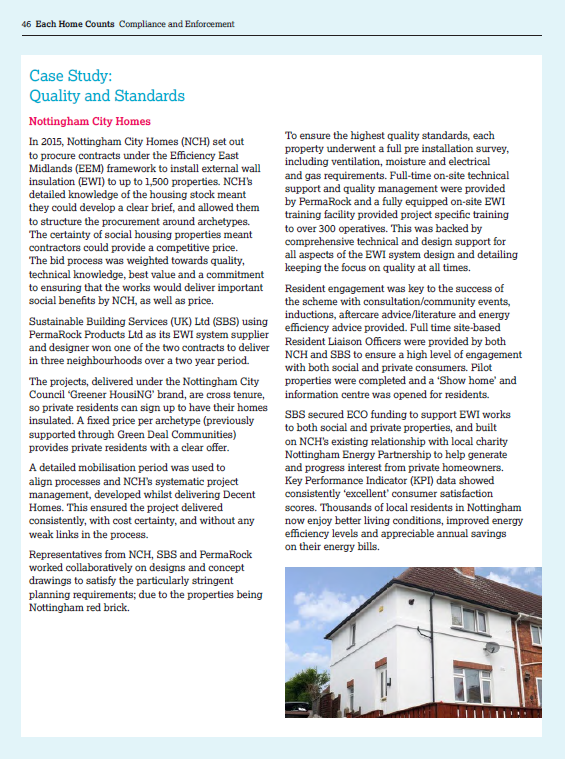

One of these examples describes the work of Sustainable Building Services, PermaRock Products Ltd and other partners in delivering a three-phase, £8M external wall insulation scheme for Nottingham City Homes.

SBS is the only such contractor to be mentioned by name in the report, which makes a number of very positive comments about the scheme’s planning, management and delivery.

“A detailed mobilisation period was used to align processes and NCH’s systematic project management… This ensured the project delivered consistently, with cost certainty, and without any weak links in the process.”

“To ensure the highest quality standards, each property underwent a full pre installation survey, including ventilation, moisture and electrical and gas requirements. Full-time on-site technical support and quality management were provided by PermaRock and a fully equipped on-site EWI training facility provided project specific training to over 300 operatives. This was backed by comprehensive technical and design support for all aspects of the EWI system design and detailing keeping the focus on quality at all times.”

“Resident engagement was key to the success of the scheme with consultation/community events, inductions, aftercare advice/literature and energy efficiency advice provided. Full time site-based Resident Liaison Officers were provided by both NCH and SBS to ensure a high level of engagement with both social and private consumers. Pilot properties were completed and a ‘Show home’ and information centre was opened for residents.”

“SBS secured ECO funding to support EWI works to both social and private properties, and built on NCH’s existing relationship with local charity Nottingham Energy Partnership to help generate and progress interest from private homeowners. Key Performance Indicator (KPI) data showed consistently ‘excellent’ consumer satisfaction scores. Thousands of local residents in Nottingham now enjoy better living conditions, improved energy efficiency levels and appreciable annual savings on their energy bills.”

The findings were based on a series of inspections by independent inspectors, who visited various sites in Nottingham, as well as the purpose-made training centre. Inspectors were particularly impressed by the rigour of the quality-checking procedures implemented by SBS, the system designer, PermaRock, and by other stakeholders including E.ON and, of course, Nottingham City Homes itself.

‘Appropriate measures’

During the inspectors’ visit, SBS showed how it had worked with the EWI system designer, PermaRock, to create a training centre that precisely replicated the detailing of the 30 property archetypes. This enabled operatives to understand precisely how to apply the EWI system to each kind of property, thereby maintaining quality and speeding progress on site. This was duly noted and, again, the practices observed compared very favourably against other schemes. In a section specifically devoted to the insulation industry, the report states:

“While many successful examples of the installation of energy efficiency and renewable energy measures exist, there are also many cases of poor quality work and performance, especially in the area of insulation and fabric upgrades.

“Attempts to remedy this have been inconsistent in delivering well-constructed and appropriate measures. Homes are, for the most part, individual and any modifications need to take account of location, exposure, history, usage and state of repair, as well as architectural context. Too often there is very poor analysis and consideration of these individual factors prior to modifications being undertaken. This can be driven by scheme mechanisms to install fabric and energy efficiency measures at the lowest possible upfront cost. On occasion, inappropriate insulation has been installed in unsuitable buildings, with poor detailing or without adequate ventilation, etc. This can result in damage to the building fabric, consequent unexpected costs and health issues for the occupants.”

In the context of such concerns, the Nottingham City Homes scheme demonstrates a number of examples of industry best practice. Firstly, early supply chain collaboration helped to overcome some potentially significant obstacles with respect to planning consent. Working together four months prior to any formal contract award, SBS, PermaRock and NCH produced drawings and visualisations, product samples and bespoke detailing to show local authority planners how the proposed work would enhance the fabric and appearance of the housing stock. Consent was duly granted. Had it been delayed, some Green Deal Communities funding would have been lost and the work would have benefited far fewer families. Given that NCH prioritised its target areas in terms of social disadvantage and fuel poverty, it was especially important to maximise the scheme’s scope.

This early collaboration was specifically remarked upon in the report: “Representatives from NCH, SBS and PermaRock worked collaboratively on designs and concept drawings to satisfy the particularly stringent planning requirements; due to the properties being Nottingham red brick.”

To ensure effective working on the many different property archetypes, SBS and supply chain partners made strenuous efforts to understand all project requirements in advance, and to develop bespoke materials. All windows, doors and other features required their own special detailing. To ensure quality and speed of installation, SBS required PermaRock and suppliers of adaptation items such as window trim to supply bespoke, pre-manufactured materials for each property. This property-by-property approach demanded great teamwork, communication and logistical control but contributed greatly to rapid progress on site and exceptional quality standards.

These and other measures are examples of best practice that the National Insulation Association is now promoting UK-wide. Some months ago, in anticipation of the report, the NIA began developing enhanced industry standards and specifications for insulation measures including cavity wall insulation, external wall insulation, loft insulation and room-in-roof insulation. These will be rolled out in 2017.

More details of the NIA’s response to the ‘Each Home Counts’ report can be found here: http://nia-uk.blogspot.co.uk/2016/12/nia-response-to-publication-of-each.html

A clear emphasis on quality

Commenting on the findings of the report, SBS Chair, Derek Horrocks said: “I’m very pleased to see such a clear emphasis being placed on quality standards. ‘Each Home Counts’ makes many very important points about the industry as a whole. It’s essential for the future and reputation of this sector that contractors and systems designers work together to raise standards and introduce robust mechanisms for design, installation, inspection and – where appropriate – rectification.

“As a business, we have worked extremely hard to observe the very highest quality standards and I’m naturally delighted that this report – by far the most significant of its kind – has cited our work as an example of best practice.

“Within the UK, fuel poverty remains a massive challenge for the industry and, as the report points out, consumer trust is vital. Key to achieving this is the industry’s ability to deliver a reliable service, backed by a solid consumer protection framework, and our ability to give householders confidence that work will be done to a high standard. Dr Bonfield’s report has called for precisely these kind of changes – including the establishment of a new quality mark – and I wholeheartedly support his recommendations.”

A copy of the report ‘Each Home Counts’ can be downloaded here.